RETAIL & INDUSTRIAL SOLUTIONS

Our Company

Adler Instrument UK, founded in the year 2009, is a reputed company that designs and manufactures various Retail and Industrial Weighing solutions. Adler Instrument FZCO is the regional office based in Dubai, which supplies and manages its operations in the Middle East and Africa. We are leading company in the design and manufacture of our Flagship All-in-One POS solutions for the retail and hospitality industry.

ADLER has also been an innovator in the development and manufacture of high-quality and high-performance Retail & Industrial weighing solutions. The solutions we design are based on the factors like ‘application & industry’, ‘process monitoring’, and ‘functionality’ required. We work closely together with our partners to help provide solid solutions for a wide array of applications across a diverse range of industries.

Solution We Offer

Industrial Weighing & Automation

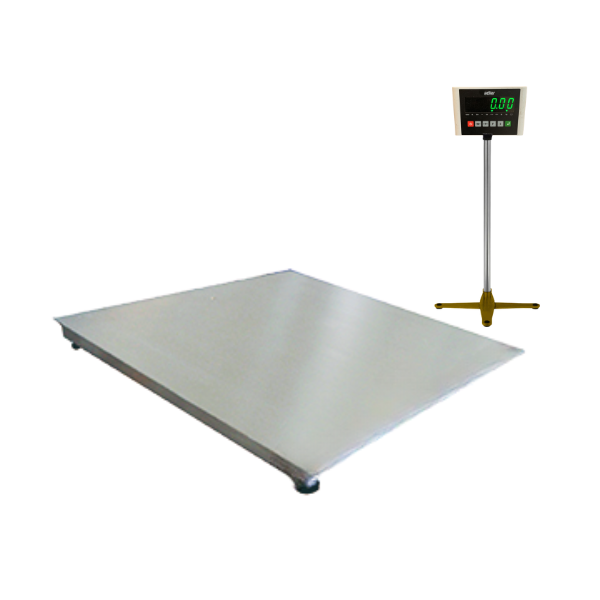

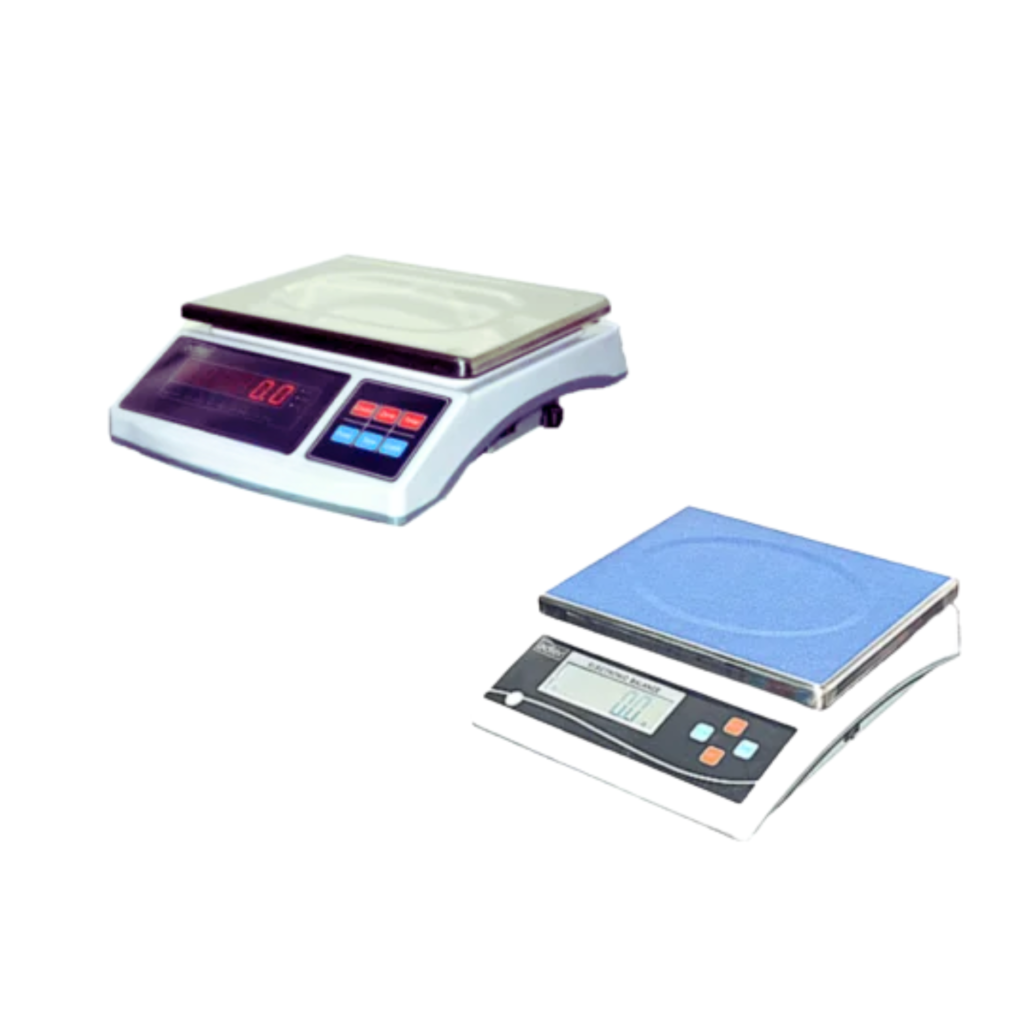

Our weighing automation solutions are designed to streamline your weighing processes, improve accuracy, and increase efficiency. With our solutions, you can automate your weighing operations, reduce manual errors, and enhance productivity. Moreover, Adler Instrument FZCO is a well-known supplier for Precision Balance, Table Top Weighing Scale, Waterproof Weighing Scale, Platform Weighing Scale, Floor Weighing Scale, Label Printing Scale, and all types of Industrial Electronics Weighing Scale throughout the UAE

Industrial solution

Our industrial solutions are designed to transform industries by providing innovative technologies and expertise that improve efficiency

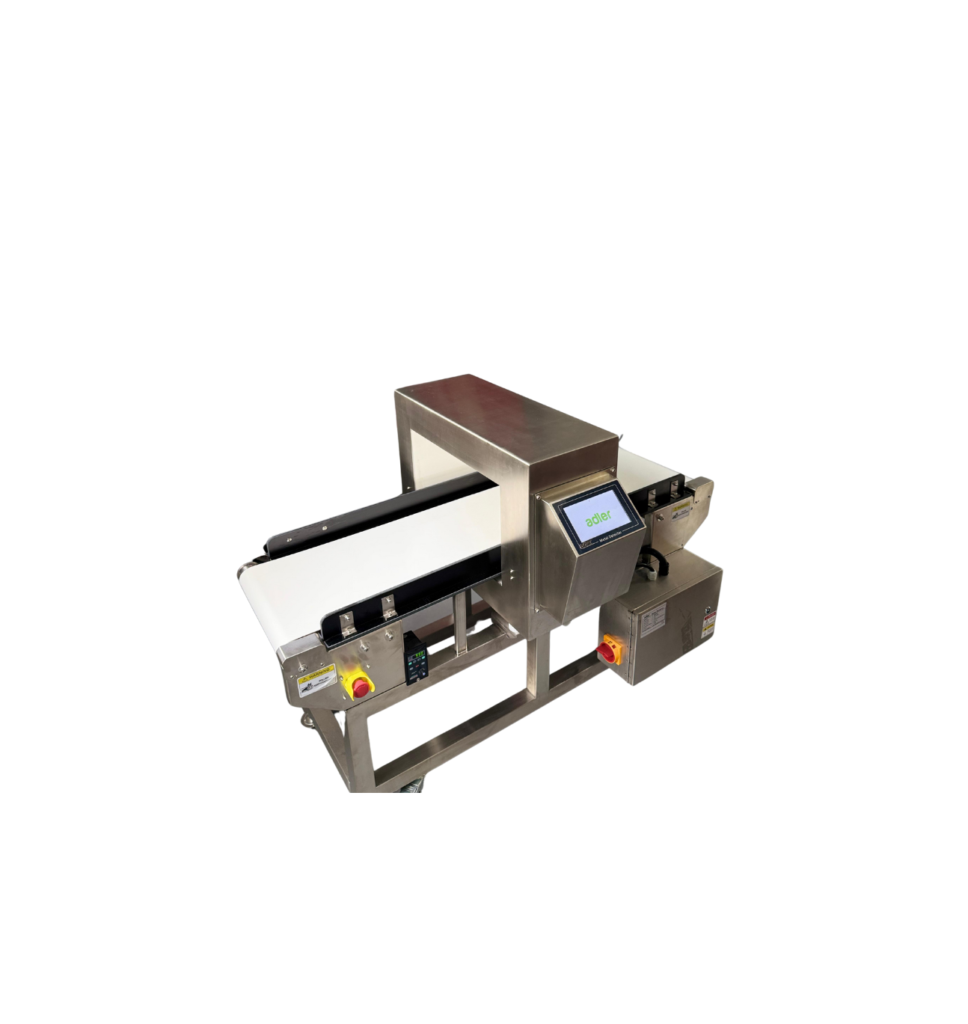

Product Inspection Solutions

Ensuring Quality and Safety

Our product inspection solutions are designed to detect contaminants, defects, and irregularities in products, ensuring quality and safety across various industries.

We're Offering

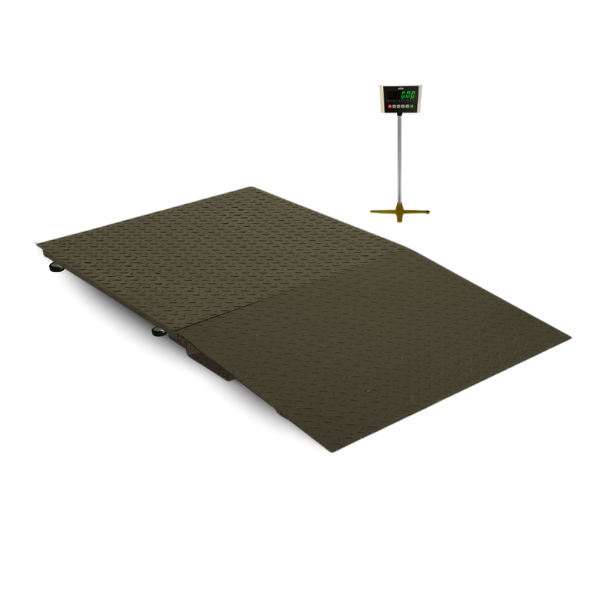

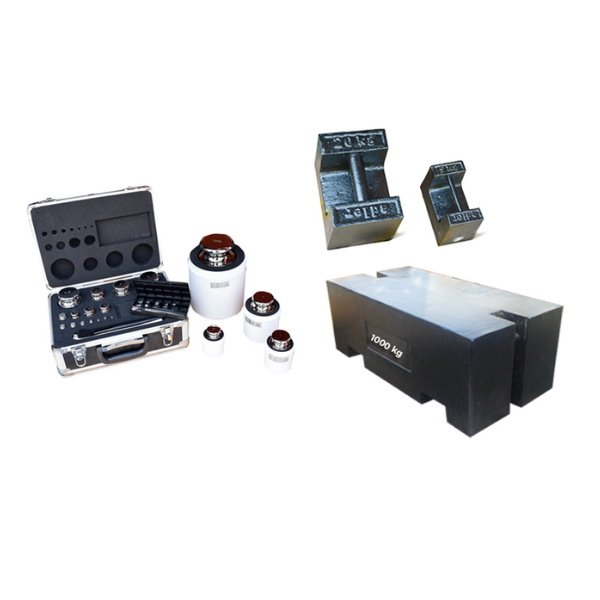

Adler Instrument FZCO is a leading supplier and manufacturer of Industrial weighing scales/weighing machine in the UAE, offering a comprehensive range of products including precision balance, label printing scales, tabletop weighing scales, waterproof weighing scales, platform weighing scales, roller weighing scales, floor weighing scales, animal weighing scales, pallet weighing scales, coil weighing, weighbridge, unmanned weighbridge solutions, Standard weight. Product Inspection:-(Check-weigher, Metal Detector, X-Ray) Additionally, we provide weighbridge software, POS terminals, and retail software. Our services extend throughout Dubai, Abu Dhabi, Sharjah, all over the UAE and GCC region.

Our experienced team is dedicated to providing exceptional customer service and support, assisting you in selecting the right weighing equipment for your specific requirements. We also offer installation, maintenance, and calibration services to ensure your scales remain in optimal condition.

Whether you are looking for a simple and best digital weighing scale for your retail store or a complex industrial weighing system, we have the expertise and resources to deliver tailored solutions that meet your needs. Explore our extensive product catalog and experience the difference of working with a trusted leader in the weighing industry. Contact us today to learn more about how we can support your business with our advanced weighing technologies.

Products

Platform Weighing Scale

Bench Scale / Check Weigher

Metal Detector

Check Weigher

Floor Weighing Scale

Table Top Scale

Waterproof Scale

Label Printing Scale

Pallet Jac Scales/ Pallet Weighing Scale

Roller Scale

Floor Weighing Scale with Ramp

Standard Weights

Weighbridge

Adler weighbridge:-Also known as a truck scale, measures the weight of large vehicles and loads, ensuring compliance with weight regulations and preventing overloading. Installed at locations like shipping docks and industrial sites, they come in pit-mounted and surface-mounted designs to suit specific needs. Equipped with digital displays and software, weighbridges also offer data storage and analysis for logistics and operations management.

Adler Unmanned weighbridges:- are automated systems that streamline the weighing process without human intervention. They’re ideal for logistics, mining, and manufacturing industries, where efficient and accurate weight measurements are crucial.

Key Features:

Automated Weighing:- Unmanned weighbridges use advanced sensors and systems to automate the weighing process, reducing manual labor and increasing efficiency.

High-Precision Load Cells:- These systems ensure reliable weight measurements, often with high-precision load cells that provide accurate readings.

Camera Integration:- IP cameras capture live footage of vehicles during weighment, including license plate details and vehicle images.

Vehicle Identification System:- RFID or barcode scanners identify vehicles, eliminating manual data entry and reducing errors.

Traffic Lights and Boom Barriers:- These features regulate traffic flow and ensure safe operation

Tank Weighing

Adler Tank weighing system:-

An essential tool in various industries, ensuring accurate measurement and monitoring of liquid or material levels within a tank. This system typically involves load cells strategically placed to capture weight data and a digital indicator or controller that processes and displays the information. Businesses can optimize inventory management, enhance process efficiency, and maintain compliance with regulatory standards by using such a system. Innovations in technology have made these systems more reliable, with features like wireless data transmission and advanced analytics capabilities, providing users with real-time insights and improved operational control.

Tank weighing systems:- utilize load cells to measure the weight of liquids or materials stored in tanks.

Tank Weighing Systems

1. Applications: Chemical processing, oil and gas, food and beverage, and pharmaceutical industries.

2. Benefits: Accurate weight measurement, inventory management, and process control.

3. Components: Load cells, mounting hardware, and signal processing equipment.

Compression Load Cells:-

1.Principle: Measure the compressive force exerted on a structure.

2.Characteristics: High accuracy, reliability, and suitability for compression applications.

Shear Beam Load Cells:-

1. Principle: Measure the shear force exerted on a beam due to weight or force.

Customized Solutions

Manual Filling, Batching, and Dosing

Adler customized product – filling, batching & dosing systems:-are designed to meet specific industry needs, ensuring accurate and efficient production processes. Adler Instrument FZCO is the regional office based in Dubai. Our continuous efforts focus on innovation and improvement, allowing us to offer cutting-edge solutions that enhance customer satisfaction and foster long-lasting relationships. We believe that by collaborating closely with our clients, we can achieve exceptional results together.

Filling:– containers with a specific quantity of material, such as liquids, powders, or granules.

Batching:– Measuring and combining ingredients or materials in specific quantities to create a batch or mixture.

Dosing:-Measuring and dispensing a precise quantity of material, often in small amounts.

Key Features

High-precision weighing:- Accurate batching and filling capabilities to minimize errors and ensure product consistency

Flexible formula management:- Ability to change formulas and settings as needed, with options for printing reports or a label

Real-time data management:- Integrated data management solutions for monitoring performance, identifying inefficiencies, and informed decision-making. Customization: Systems can be tailored to meet specific industry requirements, such as pharmaceutical, food and beverage, or cosmetics production

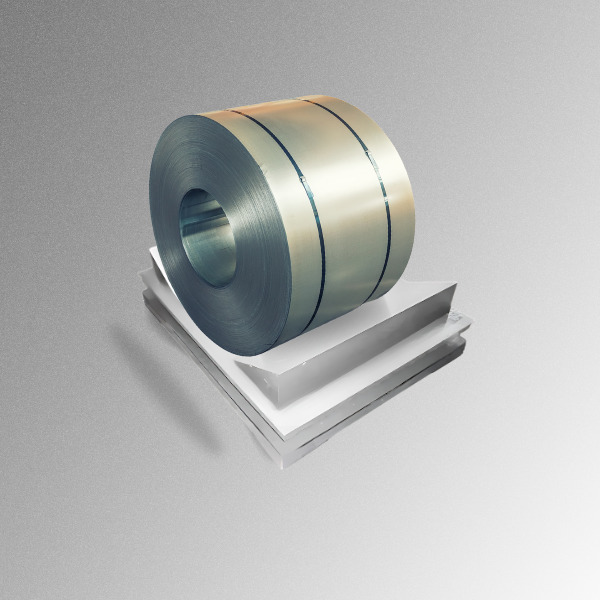

Coil Weighing

COIL WEIGHING is a critical process in industries that handle large rolls or coils of material, such as steel, aluminum, or paper. Accurate weighing of coils ensures that the correct amount of material is shipped, prevents overloading of transport vehicles, and helps maintain inventory control.

There are several methods for coil weighing, each suited to different operational needs. One common method involves using a coil scale, which is a type of platform scale designed to accommodate the unique shape and weight distribution of coils. These scales can be floor-mounted or integrated into a conveyor system for seamless weighing during production.

Accuracy in coil weighing not only enhances operational efficiency but also contributes to customer satisfaction by ensuring that specifications are met consistently. As industries continue to evolve, innovations in coil weighing technology are expected to provide even more reliable and efficient solutions.

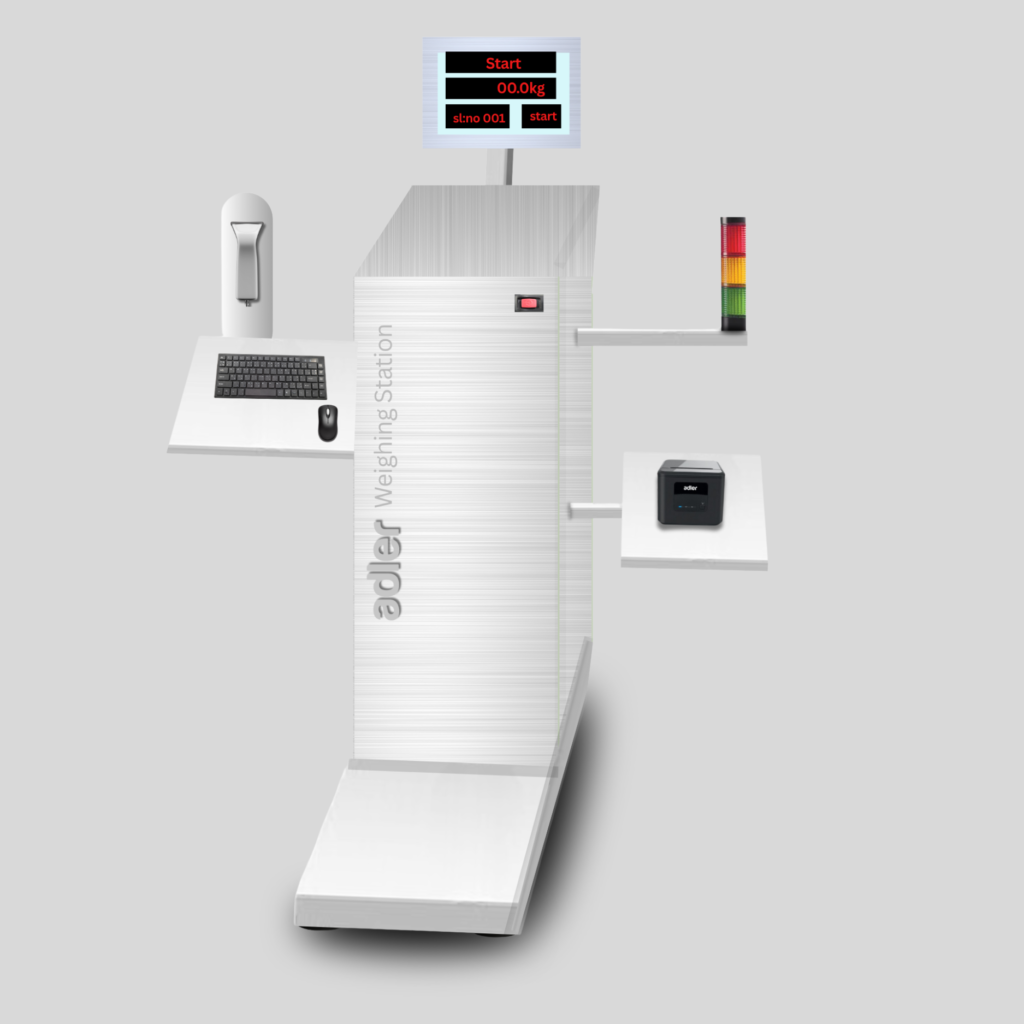

Roller Weighing Scale/Conveyor Weighing Scale

Conveyor weighing scale:- This is essential in many industrial settings, as it plays a crucial role in ensuring accuracy and efficiency in heavy materials without lifting, which can be connected to production lines and material handling processes. These scales are designed to integrate seamlessly with conveyor systems, enabling continuous weighing of products as they move along the production line and providing additional tower lamp for easy visual feedback. This not only helps maintain product consistency but also aids in quality control, inventory management, and cost reduction. By providing real-time data, conveyor weighing scales allow operators to make informed decisions quickly, enhancing overall productivity. Moreover, they can be customized to suit specific industry needs, whether in food production, logistics, or manufacturing, making them a versatile solution for modern business

Additional option:- The height can be adjusted; a roller ramp can be attached to the system to avoid lifting and time delay, like rice bags in the warehouse or other heavy materials weighing, and customized weighing data for the product can be provided

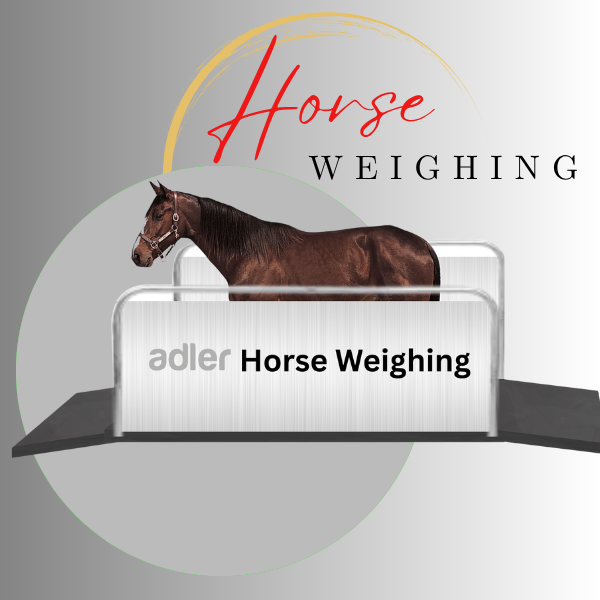

Horse Weighing

Horse Weighing

Horse weighing and data collection are essential for monitoring a horse’s health, growth, and performance. designed specifically for weighing horses with a customized data storage and other functionality, a non-slippery surface, the size and capacity vary depending on the horse’s size and weight, ensuring that the equipment can accommodate different breeds and ages. Regularly tracking a horse’s weight can provide valuable insights into its nutritional needs, detect any potential health issues early, and help tailor exercise regimens to optimize performance. With advancements in technology, modern weighing systems often come equipped with digital displays and connectivity options, allowing for easy data transfer and analysis. This enables horse owners, trainers, and veterinarians to make informed decisions, ensuring the well-being and peak condition of these magnificent animals.

Benifits

Health monitoring:- Regular weighing helps track a horse’s health and detect potential issues.

Performance optimization:- Accurate weight measurements enable targeted training and nutrition plans.

Informed decision-making:- Data collection and analysis inform decisions on horse care, training, and competition.

Software Solution

Adler Instrument FZCO develops software as per the client’s requirement, automation options like automatic weighing, batching, and label printing simplify the journey, freeing you from the burdens of manual tasks. It’s like having the perfect backpack that carries your essentials, leaving your hands free to embrace the adventure. Consider the integration capabilities that seamlessly connect existing systems like ERP and SAP. This sturdy rope ties everything together, ensuring that your expedition runs smoothly, no matter the terrain. Customization is your personal touch, like choosing a trail that matches your pace and interests. Tailoring the software to specific industry or business needs is like carving your unique path through the wilderness, making each step feel just right

Mission

To be most trusted and innovative provider of weighing solution in UAE and GCC region, driving accuracy , efficiency and reliability across diverse industries

Vision

To deliver high-quality weighing systems and solutions that meet the evolving needs of our customers. We are committed to providing superior products, cutting-edge technology, and exceptional customer service.

Our Promise

We promise to provide reliable , accurate and customized weighing solution backed by dedicated customer support . From small scale operation to large industrial needs.

FAQ

Q: What types of industrial scales or products does Adler Instrument FZCO offer?

A: Adler Instrument FZCO provides/supplies the best comprehensive range of industrial weighing scales or weighing machine, including platform weighing scales/bench scale, floor weighing scales, tabletop weighing scales, waterproof weighing scales, roller weighing scales, coil weighing scale, pallet weighing scale/hand pallet truck weighing, label printing scale/retail weighing scale, laboratory weighing scale, jewellery scale and customized industrial weighing products.

Q: What industries can benefit from Adler’s industrial weighing scales?

A: Adler’s industrial weighing scales are the best customized product for various industries, including manufacturing, logistics, food processing, and construction.

D: What kind of support does Adler Instrument FZCO offer?

A: We provide expert consultation and technical support tailored to specific industries and applications, and all our products.